Chillers & Sub-Ambient Cooling

Overview

This paper addresses current trends in liquid cooled systems and focuses on chiller use and applications. This includes chiller standards and design guidelines for utilizing chillers to increase efficiency, improve performance and better maintain strict temperature control for high heat load applications. Although this article focuses on more common chiller types and form factors, it is important to note that chillers can be integrated in a wide range of variations and to speak to a thermal engineer if you are unsure of the optimal utilization.

Trend Towards Liquid Cooling Systems

Global electronification, smart technologies and technology reliance continue to rise, pushing engineers to develop more powerful chips and data technologies. One of the most significant barriers to technological advancement is managing the excess heat generated by the increase in data processing and storage as well as power generation and supply. This is true across all major industries ranging from Enterprise, 5G, and Telecom to Medical, Transportation, Energy Storage, and Industrial Automation.

New, higher power applications require more efficient cooling for high heat loads in compact volumes, leading engineers to turn to liquid solutions. Liquid has the capacity to transfer heat up to 4X higher than the capacity of forced air of the same mass. This enables improved heat transfer and higher thermal performance with increased design flexibility and scalability.

A liquid cooled system is a hydraulic circuit that typically consists of a cold plate that interfaces with a heat source in a device, hoses and pumps that circulate fluid through the system, and a heat exchanger that rejects heat into the ambient environment. These integrated systems provide highly efficient cooling capable of keeping high power applications running reliably at peak performance; however, there are some limitations.

One of the most notable challenges when working with high power devices and facilities is maintaining precise temperature control within the ambient temperature and the high heat rejection into the ambient environment. Working within the given parameters, devices cannot be cooled below ambient or intake temperatures, limiting performance and increasing outbound temperatures that can make for an unsafe environment.

Issues such as these are especially noticeable in facilities that have a large number of high power systems operating concurrently, such as data centers, or in applications that need hold very close temperature tolerances with a very wide heat load variation, such as MRI machines. In scenarios such as these, utilizing a chiller is often the most effective solution.

A chiller is a device that removes heat from a liquid via a vapor-compression, adsorption refrigeration, or absorption refrigeration cycles. They can be utilized as part of a more complex liquid system or as stand-alone systems. Chiller solutions allow cooling to sub-ambient temperatures which increases efficiency and enables tighter temperature tolerances.

Chillers Overview

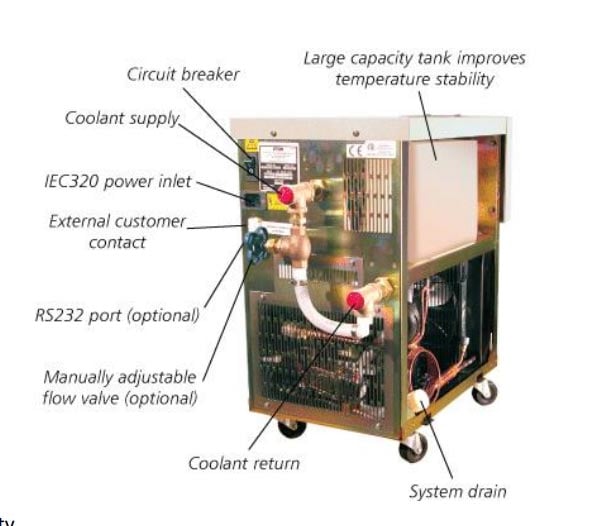

Boyd Chiller designs range from standard modular systems and stand-alone products to heavily integrated, complex systems where each component is tailored to a specific application. Standard options are developed based on the most utilized customizations for common form factors.

An example of common form factors for Boyd integrated chillers include standard 19" rack mounted and compact door mounted. Rack mounted chillers are commonly used in the server and semiconductor industries, whereas compact door chillers are used in industrial battery storage applications.

When choosing or developing a chiller for your application, it is key to optimize your components as well as the design as a whole. For example, choose a high efficiency compressor to reduce power consumption while in use or incorporate enhancements such as touch screen HMI (Human Machine Interface) or continuous level sensors for fluid reservoirs. It is crucial to evaluate each component for maximum reliability and efficiency, especially for the pump(s).

Stand-Alone / Standard

Boyd stand-alone standard chillers can operate on their own or as part of an integrated system and are typically defined and categorized by their general use specifications such as Process Temperature, Capacity, and Environment. These recirculating chillers are designed for precise temperature control or cooling below ambient temperatures.

Standard chillers are fabricated with traditional components and use water or water/glycol as the process fluid. These operate at process temperatures from room temperature down to 0o C. Components are performance matched and include optimized thermal systems and engineered materials as well as necessary mechanics such as pumps, compressors and valves.

Standard, Low Temperature & Cascade Chillers

Lower temperatures improve performance and efficiency but require variations to standard systems. Standard low temperature chillers are developed for applications that require lower process temperatures from -40oC to 0oC. Fluids used range from water/glycol mixtures to specialty heat transfer fluids. The key difference is the process fluid/refrigerant utilized.

Boyd also offers ultra-low temperature chillers that enable process temperatures from -80oC to -40oC. In order to achieve these lower temperatures, cascade refrigeration technology is employed, often using two refrigerants to two separate refrigeration loops that operate in a series.

Chillers Overview

Define Exact Requirements

Before choosing a standard chiller or beginning the concept and design process for a custom chiller, it is vital to understand the minimum requirements to establish a base model:- Heat Load

- Watts or BTU/hr.

- What is the heat load? Is it steady or fluctuating?

- Access/ Access Point to Chilled Facility Water

- A Chiller must have access to chilled water despite coolant used. Access point and integration with the rest of the liquid system affects form factor and mounting.

- Coolant Fluid

- If not employing water or water/glycol, be sure to have precise fluid details including any corrosive attributes. (See Section on Process Fluid)

- Required Coolant Temperature (set point)

- Ambient Temperature

- In-take temperature

- Flow Rate of Process Fluid (LPM or GPM)

- Required Fluid Pressure

- Be aware of fluid pressure and pressure drops.

- Power Input

- Electrical power available (volts, phase and Hz)

- Environmental Conditions

- Impacts Chiller design and engineered materials utilized. Examples include humidity, dust and particles and vibrations or shock.

Optimize Available Space

Chillers can be integrated into a large range of form factors for various applications based on the placement of components and how the chiller is attached to the device or system. These decisions effect performance, volume, reliability, and ease of maintenance. When designing chillers for different form factors, it is important to provide the most cooling in the smallest footprint available. The layout needs to consider product performance, reliability, and accessibility for servicing. It also needs to provide easy and error-proofed integration when being installed into the device.

Ensure Long Term Reliability

One of the limiting factors of utilizing chillers is the addition of more moving/mechanical components. When designing a system that includes a chiller, it is crucial to have testing, reliability, and maintenance protocols in place.

- These include considerations for:

- Remote Monitoring

- Energy Metering

- Leak Detection

- “Hot Swap” designs to avoid down time

- Maintenance Contracts

Pumps are the most significant components to evaluate in order to ensure high lifetime and reliability. Take the time to do comparisons and testing to select pumps that use less power and provide optimal pump flow for the application with required pressure head. The selection of the rest of the plumbing materials and flow components can further enhance pump performance and system efficiency.

Process Fluid

The process fluid has a significant impact on performance, usage and efficiency. Most liquid chillers utilize water or a water/glycol process fluid solution. The addition of corrosion inhibitors and biocide is critical to prevent long term corrosion and algae growth that can bring down the system by leaking or flow blockage. It is essential to understand the wetted chemistry of every surface that the process fluid touches to select the correct corrosion inhibitor. The use of glycol, which offers freeze tolerance, will likely require the use of a biocide as glycol is a very good food source for algae. There are many premade process coolants available off the shelf.

Additionally, it is important to remember that corrosion inhibitors need to be replenished over time because they are consumed over time as they passivate the surfaces they flow past. Changing out the process coolant or replenishing corrosion inhibitor chemicals is necessary preventative maintenance.

Refrigerants

Refrigerants are used in chillers as a closed loop to the process coolant, where the two do not come in direct contact with each other, and heat is transferred between the process coolant and the refrigerant. Refrigerant selection can have a significant effect on energy efficiency.

In operation, the refrigerant flow consists of both vapor and liquid. Vapor quality is the percentage of the saturated mixture that is vapor; in other words, saturated vapor has a “quality” of 100%, and saturated liquid has a “quality” of 0%. The vapor quality is a function of the operating pressure and temperature; and each refrigerant is rated for either low, medium and high pressures. This heavily impacts the selection of the compressor motor; poor refrigerant choice could offset any efficiency gains from a branded “Energy Efficient” compressor.

Green Refrigerants

New, more environmentally friendly refrigerants are becoming much more popular. Global warming potential (GWP) is the heat absorbed by any greenhouse gas in the atmosphere. It is expressed as a multiple of the heat that would be absorbed by the same mass of carbon dioxide (GWP of CO2 = 1). Older standard refrigerants such as R22 (Freon) have been replaced by a range of more environmentally friendly refrigerants with a lower GWP. This is an important consideration when choosing process fluids as global environmental regulations become stricter.Communication Options

Recent advancements in chiller design include improved connectivity, communication, and HMI. Conventional communication protocols integrate with end user systems to monitor process variables such as temperature, flow, pressure, and system health. With newer interfaces, users can control the chillers remotely as well. Some Boyd custom chiller solutions also utilize custom protocols to monitor and report based on application needs. Being able to monitor and control variables allows for peak efficiency and tighter control over the system.Cost Considerations

The overall cost of adding a chiller to a liquid cooled system is driven by selection of key components, specifically the pump, compressor, and heat exchangers. This initial cost combined with the cost of running the chiller is the overall cost of the chiller. Water cooling systems are energy efficient systems and therefore have the most efficient usage costs. Maintenance and certification costs must be considered along with these usage costs for the total cost of running the chiller.Next Steps in Choosing A Standard Chiller

Chiller adoption will continue to rise as high-power electronics continue to advance in capacity and heat load. Cost will likely be the most significant barrier to adoption. The best ways to mitigate these costs will be:- Engage a solution partner early in the process – Because there are so many factors in optimizing your chiller and liquid system to ensure performance, reliability, and costs, it is crucial to engage a design and manufacturing partner as early in the process as possible. This will ensure that you are utilizing the right chiller optimized for your exact application requirements.

- Lower initial costs – Some may try to cut costs by using sub-par or lower quality parts. This will ultimately incur much higher longterm maintenance and repair costs leading to a higher overall cost. A better choice would be to choose a standard base chiller at a lower cost than a custom model and make customizations from there. Choosing a standard from a well-vetted manufacturing partner can also cut initial costs through streamlined production.

- Maximize Energy Efficiency – By examining energy efficiency while determining design choices, chillers can run at much lower energy usage costs driving the operating costs down significantly.

- Less/ Simple Maintenance – Partner with a solution manufacturer that provides reliability testing and highly reliable components to lessen the need for repairs and maintenance. Be sure that warranties are in place and that the solutions partner has internal processes for streamlining the maintenance process.

Boyd As a Solution Partner

As power loads continue to rise, liquid cooling will continue to be adopted and adapted for existing and new applications across most major industries. Customer demands continue to grow as end users expect lighter weight, better reliability, improved features and connectivity, and faster processing. The most significant barrier to satisfying these demands is handling the vast amount of heat without hindering lifetime, user safety and performance.

This requires that Boyd liquid cooling methods advance ahead of the applications to accommodate new generation technologies and market demands. Boyd works closely with our customers to understand their product roadmaps, assess future needs, and be prepared accommodate them.

Boyd's decades of innovation expertise, experience, resource development and unique approach to integrating multiple functionalities into streamlined solutions enable us to meet new requirements and exceed expectations. Boyd has been tackling thermal challenges for over 90 years and is a pioneer for liquid solutions in enterprise, electric vehicles, 5G, alternative energy and other major industries.

Have questions? We’re ready to help!